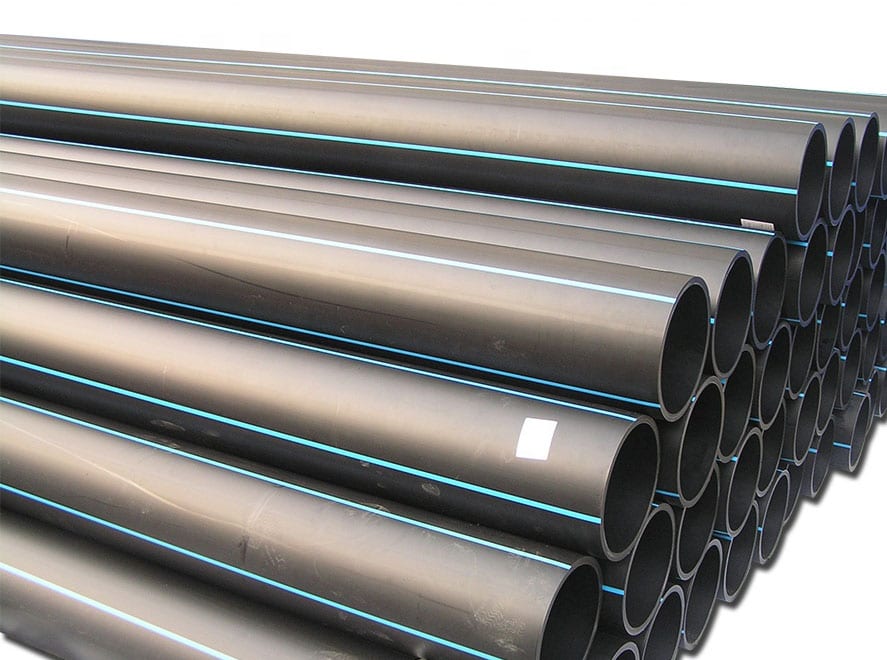

A COMPLETE PIPING PACKAGE TO MEET INDUSTRIAL NEEDS

Poly Pipe can be provided as a complete piping package to meet industrial needs by providing the highest quality polyethylene pipe with matching precision fittings that meet all applicable ASTM specifications. A wide range of diameters and walls to meet varying conditions are also offered.

Applications

- Slurry lines

- Mud lines

- Irrigation lines

- Cooling Water

- Sand transport lines

- Corrosive waste

- Dredging lines

- Sludge lines

- Acid lines

- Fly ash lines

- Caustic lines

- Dewatering lines

ADVANTAGES

- CORROSION RESISTANCE: POLY PIPE has an outstanding resistance to nearly all acids, caustics, salt solutions, and other corrosive liquids and gases. POLY PIPE can be buried in acid or alkaline, wet or dry soil. The pipe does not scale or pit; it does not rot, rust or corrode. It also resists the growth of bacteria, algae and fungi that could impede flow or cause offensive odors. It is resistant to marine biological attack.

- LIGHT WEIGHT: POLY PIPE is 10% to 30% of the weight of most other pipes of the same size. Significant cost savings can be realized by reduced manpower and lighter equipment for handling and installation of the pipe.

- FLEXIBILITY: the inherent flexibility of POLY PIPE allows it to be used in difficult conditions of terrain. The combination of flexibility and lightweight allows the pipe to be assembled in flat or other ideal areas and be pulled over hills to the installation point. This same combination allows the use of

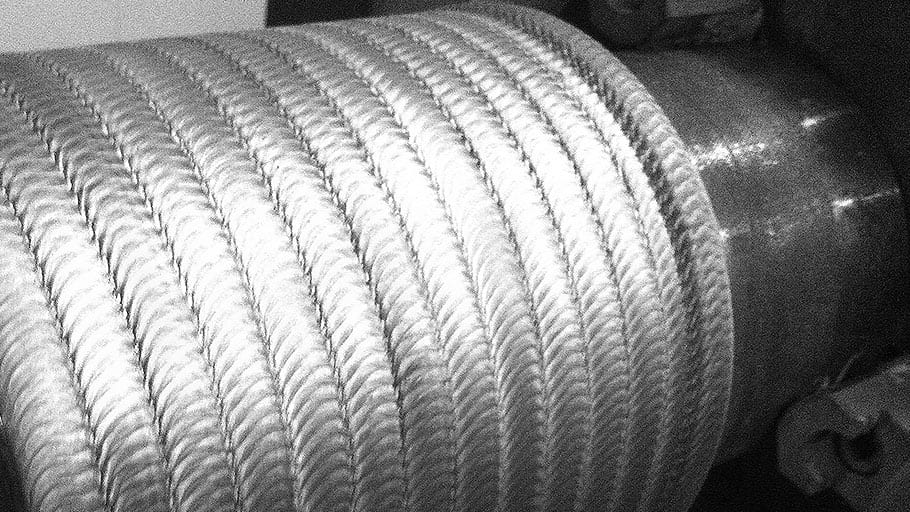

narrower trenches since the pipe can be assembled above ground and rolled into the trench. Usually the pipe can be bent to a minimum radius of 10-20 times the pipe diameter. This allows contouring the pipe around obstacles without the use of fittings. - ABRASION RESISTANCE: POLY PIPE can handle a wide variety of slurries and other abrasive materials. Generally the pipe will outlast steel pipe by a factor of four. It also outlasts rubber lined pipe. Its lightweight characteristics permits easy rotation of long lengths.

- FLOW CHARACTERISTICS: POLY PIPE has an extremely smooth inner surface which offers very low resistance to flow.

- RESILIENCY: POLY PIPE can be deformed percussively without permanent damage under and increasing external load to more than half its original diameter. The pipe will flex with impact loads over a wide temperature range from – 180°F to 180°F without brittleness. The expansive force of water freezing in the pipe will not crack POLY PIPE.

- COST SAVINGS: Compared to conventional jointed pipe, the use of POLY PIPE can result in significant cost savings in installation, labor and equipment, reduced maintenance over the life of the pipeline and freedom in design.

- MATERIAL DESIGNATION: POLY PIPE is made of high density, high molecular weight polyethylene. The polyethylene base resin meets all requirements of ASTM 0-1248 for Type 111, Grade P34, Category 5, and has a PPI rating of PE3408 by the Plastic Pipe Institute. The average physical property values for POLY PIPE and fittings at 73.4°F are shown on pages to follow.