Please contact us for more information on our Machining Services.

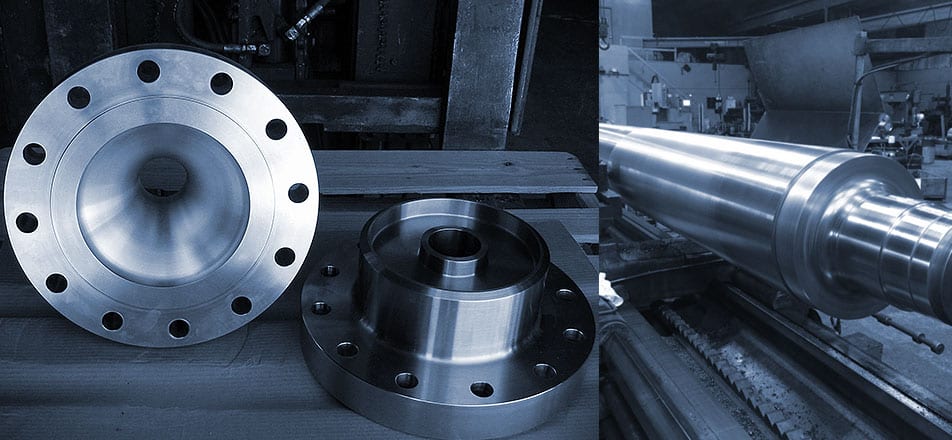

Machining Services

As a Manufacture Representative for several Machining Facilities Walker Services can provide a wide product service in Machining Services. Another advantage in working with WS is that you are assured of getting the most economical price within the market. This is possible because of our Machining Services Network. A total of 3 to 4 machining facilities maybe utilized in the quotation process. Each facility is evaluated based on workload, location to plant, expertise, delivery dates, certification and pricing. In today’s Industrial world, in some cases, the end users do not have the time or manpower to shop for the best job.

Allow Walker Services to provide this service for you. Below is a list of several Machining Services available through Walker Services Inc.

Laser Machining

- High wattage carbon-dioxide laser systems with over-sized tables

- Can cut tubular or flats

Critical Machining Specialties

- Large Part Machining

- 14’ diameter x 40’ long lathe capacity

- CNC machine for consistent quality and increased production

- Gear Train Housings

- Tapered dryer journals

- Worn gears rebuild

Our Diversity:

- CNC Lathes

- CNC Mills

- 4-Axis CNC Machining Centers

- Manual Machining equipment

- Short runs and Prototypes

- Production Runs

- High-Volume

- Precision / Close-Tolerance

- Custom Parts

- Assemblies

Stamping

- Stamping and forming capabilities allowing turnkey projects

- Wire EDM Services

Portable Machine Works, On-sight Field Services

PMW responds to your on-site needs 24 hours a day. Portable Machine Works many years of experience coupled with our superior equipment enables us to reduce expensive down time and lower your maintenance costs.

- Back Facing Heat Exchangers

- Re-Machining Flanges on large Vessels

- Machining RTJ grooves in flanges

- Cutting and beveling pipe

- Machining shaft keyways in place

- On-site cutting and milling

Custom Tungsten Carbide Inserts & Forming Tools

- Offset Tool Holders

- Precision ground inserts to your exact design

specifications. - Tungsten Carbide form tools provide accuracy

and repeat-ability for blueprint applications. - Form tools can increase productivity by

combining grooving and profiling in one

operation.